UM/Schneider Electric Collaboration : New dielectric materials for electric field graders

Project coordinator :

- Renaud Metz, L2C, Montpellier

Partners :

- Schneider Electric

Project goal :

The electrical insulation of medium-voltage electrical equipment (HTA) has historically been provided by sulphur hexafluoride (SF6). This gas is one of six types of greenhouse gases covered by the Kyoto Protocol and Directive 2003/87/EC. Its global warming potential (GWP) over 100 years is 23,500 times greater than that of carbon dioxide.

In this context, eliminating it from the design of new installations is of most importance. This industrial transition is not problem free. Dielectrics are subject to very high electric fields.

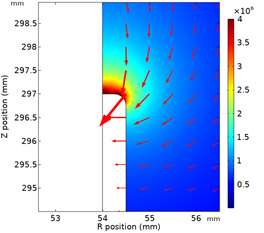

One solution for confining these excess electric fields is to use new dielectric materials with non-linear conductivity-field characteristics.

Above a certain threshold electric field, the volume conductivity increases with the electric field: σ =f(Eα), avec α > 4. We are developing composite dielectrics with a polydimethylsiloxane matrix loaded with carbon-based micro- and nano-particles.

Our research aims to understand the physical mechanisms behind nonlinearity effects through an experimental approach compared with simulations, and to determine an efficient protocol for implementing these materials on a pilot scale.